Tooling -Made to Order!

Solid Carbide

Cutting Tools

from SFS Carbide

Precision Carbide Cutting Tools

OUR CUSTOM AND STOCK CARBIDE CUTTING TOOLS

CUSTOM TOOL MAKING

Give us a sample, or blue print, and we can make your exact tool!!

Drills – Routers – Reamers – End Mills – Carbide Burrs – Port cutting tools

OUR TYPES OF CUTS

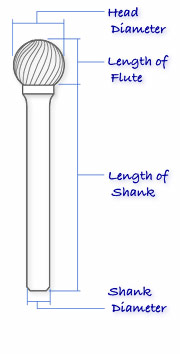

TUNGSTEN CARBIDE TOOLS

Tungsten carbide cutting and boring tools are smaller now than ever before, and seem to be getting smaller every year. To meet this challenge, SFS Carbide Send SFS your carbide bur specifications for a custom tool cutting tools are fabricated exclusively from the advanced tungsten carbide composites developed and supplied by domestic and foreign suppliers. Ultra-fine grain cemented ceramics are the result of an extensive development program aimed at optimizing the very best of cemented carbide technology to achieve an exceptional combination of hardness, toughness, and strength for demanding cutting jobs.

These extraordinary properties have been achieved by producing tungsten carbide with a grain size of only 0.4 micron. We select grades of solid carbide blanks to accommodate the application at hand from precision dental drills to industrial reamers and engine cylinder ball cutters. Generally speaking, the need for reliable small hole drilling and the accompanying demand for extended tool life has necessitated the use of the finest grades of carbide currently available. The bulk of our tools are fabricated from 6 to 10% cobalt blanks, which are recommended for solid carbide rotary tool applications. Call SFS engineers to discuss any of your CNC machining tool requirements.

PRECESSION CUTTING TOOLS

CNC controllers are devices that control machines and processes. They range in capability from simple point-to-point linear control to highly complex algorithms that involve multiple axes of control. CNC controllers can be used to control various types of machine shop equipment. These include horizontal mills, vertical mills, lathes, programable drill presses, turning centers, metal grinders. The number of axes controlled by CNC controllers can range anywhere from one to five, with some CNC controllers configured to control greater than six axes. All need cutting tools made for specific applications. Made to order from blue print drawings, or from submitted samples.

AND FAR MORE

SFS Carbide Tool Catalog

11.2MB (high resolution)

The Right Tool for the Job Does Make a Difference

SFS Carbide Tool Catalog

11.2MB (high resolution)

SFS Carbide Tool Catalog

1.4MB (low resolution)

- We provide manufacturing to exact specifications.

- Products are inspected multiple times during the production process to ensure consistency and product integrity.

- All products are produced to extend tool life by using only the highest quality materials to enhance their performance at our Michigan plant for all machining applications.

- Automotive CNC Blueprinting of cylinder heads and other High-Performance engine block finishing requires special cutting and polishing tools. The term "blueprinting" describes machining an engine block to exact factory specifications. The block must be bored and all the deck surfaces milled according to the crankshaft centerline. SFS excels in making the tooling for automotive, aviation and motorcycle engine building applications.

- Our 90 years of experience, as a precision metalworking toolmaker and manufacturer, is matched only by our willingness to take on tooling jobs ignored by our competition.

SFS Carbide Tool Co. Inc.

Saginaw, Michigan 48601

Office Phone: 1-989-777-3890

Fax number: 1-989-777-3860

Cell phone Bob White: 1-248-840-0090

Monday – Friday: 6:00 am – 3:30 pm EST

Email our Staff

The SFS Carbide Tool Co.

Since 1921, SFS has supplied a wide range of cutting tools to a diversified number of industries worldwide. Specialty tool and die shops and machinery manufacturers have come to us through the years for custom tool making projects. In year 2000, SFS introduced it’s line of Sidewinder Vinyl Blades to meet the needs of the signage industry that required ultra sharp durable cutting tools to slice through a wide variety of vinyl sign material.

Currently our Carbide tipped routing, milling and finishing tools have been used by major Hi-performance engine builders furnishing NASCAR and other auto racing applications. SFS provides engine cylinder head finishing tools accurate to a millionth of an inch.

EMAIL OUR STAFF

Business Hours: Monday – Friday: 6:00 am – 3:30 pm EST