Solid Carbide Port Cutting Tools for Engine Building Applications..

Precision Carbide Cutting Tools

SFS PORT CUTTING TOOLS

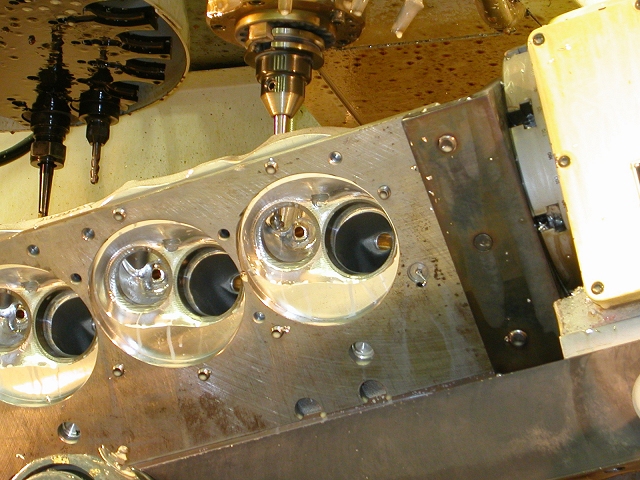

Port Cutting Tools for the motorsport industry are yet another type of precision, solid carbide specialty tool manufactured by SFS IN SAGINAW, MI. Porting a car engine’s cylinder head refers to fine-tuning the shapes of the ports that direct airflow to and from the cylinders. To improve its process for porting, a manufacturer of high-performance heads for racing engines will use a multitasking machine that is capable of milling and turning under CNC control.

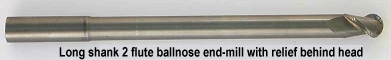

We have port cutting shank diameters vary from 1/4″ to 1″ with overall lengths to 3 1/2 inches long and neck diameters 1/8th inch to 1″ depending on customers needs. Taper lengths behind the Carbide ball cutter head can be up to 10″ long. Helix angle from straight to 60 degrees with the number of cutting flutes based upon customer specs. True balls can be made to specific diameters within .0005 and concentricity from head to shank within tenths….

CYLINDER HEAD PORT CUTTING

For increasing performance, our made to order Port Cutting Tools are used to port and finish aluminum and cast iron cylinder heads and manifolds. The most popular porting tools are manufactured on 1/2″ and 3/4″ OD shanks. Other solid carbide shank diameters are also available, as well as variable lengths depending on the porting job. ALL OF OUR CUTTERS ARE SOLID MICROGRAIN CARBIDE. Each tool is custom MADE TO ORDER from our inventory of centerless ground, carbide blanks, to a specified HEAD DIAMETER, OVER ALL LENGTH (OAL). AND TAPER BEHIND HEAD TO O.D. (OUTER DIAMETER). SFS porting tools are currently performing well in 5-axis CNC aluminum cylinder head applications, including high speed and feed situations.

To reduce chatter, SFS also offers a cutter with CHIPBREAKING GROOVES for increased performance – WITHOUT SACRIFICING FINISH (Chipbreaker groves do not overlap ) . CHIPBREAKERS can allow increased cutting speeds and feeds. See some sample SFS fluted port cutters below.

QUALITY OF OUR PORTING TOOLS

CAST IRON – Cast iron when being machined produces both chips and powder residue. SFS has spent many R&D hours to develop unique fluting geometry which combines both the advantages of a bur and an end mill in cast iron porting applications. This new geometry evacuates both chips and resedue powder faster; which translates into INCREASED PERFORMANCE, LONGER TOOL LIFE, and REDUCED MACHINING TIME.

SFS REHEADING SERVICE

CUSTOMIZE YOUR TOOL!

Below is a diagram to custom manufacture a tool to meet your requirements for both a roughing and finishing porting tool. All SFS staff needs to give you a custom quote on a Carbide Port Cutting Tool is the dimensions shown in the image below….

Fill out your order today!

OUR MACHINES

RED RHINO 5 AXIS CNC CYLINDER MACHINE.

Complete turn-key CNC Cylinder head porting package. The powerful yet easy to use the CENTROID M400 CNC control will digitize your hand shaped Intake, Exhaust and combustion chambers in 5 axes. Easy export to Mastercam X via the ethernet LAN or USB port to create the toolpaths. Inverse time toolpaths are generated for the smoothest fastest cut possible. Very little hand work is necessary after the machine has ported the head.

CNC Tools for Engine Builders matches just the right SFS Carbide Tipped tool for the job. A new casting is placed on the machine, the operator sets the Zero point, loads the cutting tool and the control machines the exact shape that was copied from the original hand shaped port. Rough and finish passes are automatically created. CNC Intake, Exhaust and Combustion Chambers are all created in this way.

RED RHINO 5 BENEFITS

- 5 axis AC servo CNC machining center

- CENTROID M400 CNC control

- TRT-25-100 CNC Tilt table

- DP-4 Digitizing Probe package

- TT-1 Auto Tool Set

- Mastercam X (5 axis CAD/CAM software)

- Cylinder head fixture plate

- Special Tooling just for CNC Porting

- Comprehensive CNC cylinder head porting training

The Right Tool for the Job Does Make a Difference

SFS Carbide Tool Catalog

11.2MB (high resolution)

SFS Carbide Tool Catalog

1.4MB (low resolution)

- We provide manufacturing to exact specifications.

- Products are inspected multiple times during the production process to ensure consistency and product integrity.

- All products are produced to extend tool life by using only the highest quality materials to enhance their performance at our Michigan plant for all machining applications.

- Automotive CNC Blueprinting of cylinder heads and other High-Performance engine block finishing requires special cutting and polishing tools. The term "blueprinting" describes machining an engine block to exact factory specifications. The block must be bored and all the deck surfaces milled according to the crankshaft centerline. SFS excels in making the tooling for automotive, aviation and motorcycle engine building applications.

- Our 90 years of experience, as a precision metalworking toolmaker and manufacturer, is matched only by our willingness to take on tooling jobs ignored by our competition.

SFS Carbide Tool Co. Inc.

Saginaw, Michigan 48601

Office Phone: 1-989-777-3890

Fax number: 1-989-777-3860

Cell phone Bob White: 1-248-840-0090

Monday – Friday: 6:00 am – 3:30 pm EST

Email our Staff

The SFS Carbide Tool Co.

Since 1921, SFS has supplied a wide range of cutting tools to a diversified number of industries worldwide. Specialty tool and die shops and machinery manufacturers have come to us through the years for custom tool making projects. In year 2000, SFS introduced it’s line of Sidewinder Vinyl Blades to meet the needs of the signage industry that required ultra sharp durable cutting tools to slice through a wide variety of vinyl sign material.

Currently our Carbide tipped routing, milling and finishing tools have been used by major Hi-performance engine builders furnishing NASCAR and other auto racing applications. SFS provides engine cylinder head finishing tools accurate to a millionth of an inch.

EMAIL OUR STAFF

Business Hours: Monday – Friday: 6:00 am – 3:30 pm EST